Insulation Materials

Insulation materials cover a broad spectrum, ranging from voluminous fiber materials like fiberglass, rock and slag wool, cellulose, and natural fibers to rigid foam boards and streamlined foils. Bulky materials excel in resisting conductive heat flow within building cavities, with some capacity to mitigate convective heat transfer. On the other hand, rigid foam boards utilize trapped air or another gas to impede heat flow effectively. Highly reflective foils, featured in radiant barriers and reflective insulation systems, redirect radiant heat away from living spaces, proving particularly advantageous in cooling climates. Additionally, less conventional options such as cementitious and phenolic foams, along with vermiculite and perlite, provide alternative solutions for specific insulation needs. This diverse array of materials allows for tailored insulation approaches, considering factors like thermal conductivity, environmental impact, and climate requirements.

Learn about the following insulation materials:

- Fiberglass

- Mineral wool

- Cellulose

- Natural fibers

- Polystyrene

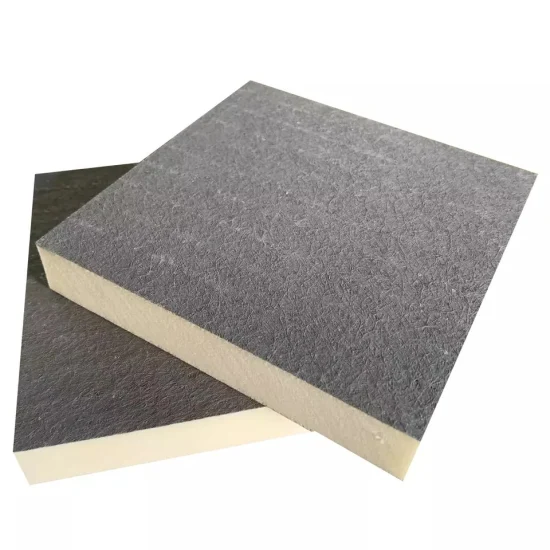

- Polyisocyanurate

- Polyurethane

- Perlite

- Cementitious foam

- Phenolic foam

- Insulation facings

Fiberglass

Fiberglass stands as a pervasive insulation material, consisting of exceptionally fine glass fibers and finding versatile use in various insulation formats. Widely employed in blankets (batts and rolls), loose-fill, rigid boards, and duct insulation, it caters to diverse insulation needs.

Recent advancements have led to the production of medium- and high-density fiberglass batts with slightly elevated R-values compared to standard batts. These denser products are designed for insulating confined spaces, such as cathedral ceilings, offering improved thermal performance. For instance, high-density fiberglass batts for a 2 by 4-inch stud-framed wall boast an R-15 value, surpassing the R-11 of “low density” types. Similarly, a medium-density batt provides an R-13 for the same thickness. The R-values increase with thickness, with high-density batts for 2 by 6-inch frame walls offering R-21 and those for 8.5-inch spaces yielding about an R-30 value. Batts with R-38 for 12-inch spaces are also available.

Manufactured from molten glass spun or blown into fibers, fiberglass insulation incorporates 40% to 60% recycled glass content for sustainability. In loose-fill form, it requires an insulation-blowing machine for application in open-blow settings like attics or closed-cavity applications within existing walls or covered attic floors.

An innovative variation of fiberglass loose-fill insulation is the Blow-In-Blanket System® (BIBS), applied dry. BIBS stands out for its effective coverage, surpassing other fiberglass insulation forms like batts. Notably, the BIBS HP represents an economical hybrid system, combining BIBS with spray polyurethane foam for enhanced insulation performance. This progressive approach underscores the continuous evolution of fiberglass insulation technologies to meet evolving efficiency and sustainability standards.

Mineral Wool Insulation Materials

The term “mineral wool” encompasses two main types of insulation materials: rock wool and slag wool. Both of these are man-made materials designed for effective thermal insulation, each utilizing different raw materials in their production.

- Rock Wool:

- Rock wool is composed of natural minerals such as basalt or diabase. These minerals are melted at high temperatures and then spun into fibers to create the insulation material. The resulting product is resistant to fire and offers thermal insulation properties.

- Slag Wool:

- Slag wool is another type of mineral wool, manufactured from blast furnace slag. Blast furnace slag is the waste material that forms on the surface of molten metal during the extraction process. Similar to rock wool, slag wool is created by melting the slag and transforming it into fibers suitable for insulation.

Mineral wool insulation is notable for its environmentally friendly characteristics. It contains an average of 75% post-industrial recycled content, contributing to sustainability and resource conservation efforts. Importantly, mineral wool doesn’t require additional chemicals to make it fire-resistant, as its inherent properties provide natural fire resistance.

Mineral wool insulation is available in various forms, including blankets (batts and rolls) and loose-fill. This versatility makes it suitable for a range of applications, from residential and commercial construction to industrial settings. The fire resistance, thermal performance, and eco-friendly composition make mineral wool a popular choice in the insulation market.

Cellulose Insulation Material

Cellulose insulation, a sustainable and environmentally friendly choice, is crafted from recycled paper products, primarily newsprint, boasting an impressive recycled material content ranging from 82% to 85%. The manufacturing process involves reducing paper to small pieces and fiberizing it, resulting in a tightly packing product ideal for filling building cavities.

To enhance its properties, manufacturers introduce the mineral borate, often blended with ammonium sulfate, ensuring resistance to fire and insects. When installed at proper densities, cellulose insulation demonstrates the valuable characteristic of not settling in building cavities.

This insulation material finds application in both new and existing homes, serving as loose-fill in open attic installations or dense-packed in building cavities such as walls and cathedral ceilings. For existing structures, a specific installation process involves removing a strip of exterior siding, drilling three-inch holes into each stud bay, and using a filler tube to blow the insulation into the wall cavity, achieving a density typically ranging from 1.5 to 3.5 lb. per cubic foot. After installation, the holes are sealed, and the siding is restored to match the wall.

In new construction, cellulose insulation can be either damp-sprayed or installed dry behind netting. Damp-sprayed cellulose involves adding a small amount of moisture at the spray nozzle tip, activating natural starches in the product, which causes it to adhere inside the cavity. This type of cellulose is often ready for wall covering within 24 hours of installation. Alternatively, cellulose can be blown dry into netting stapled over building cavities, providing flexibility in installation methods for construction projects. The versatility, sustainability, and fire-resistant properties make cellulose insulation a favorable choice for a range of insulation needs.

Several natural fibers, including cotton, sheep’s wool, straw, and hemp, serve as insulation materials, providing sustainable alternatives to traditional options.

Cotton:

- Cotton insulation is composed of 85% recycled cotton and 15% plastic fibers treated with borate, offering flame retardancy and resistance to pests. Some products use recycled blue jean manufacturing trim waste, minimizing energy consumption during manufacturing. Cotton insulation is available in batts.

Sheep’s Wool:

- Sheep’s wool, treated with borate to resist pests, fire, and mold, serves as insulation material. Batts designed for 2 by 4-inch and 2 by 6-inch stud-framed walls provide R-13 and R-19 values, respectively.

Straw:

- Straw bale construction, which gained popularity on the Great Plains 150 years ago, has seen renewed interest. The process of fusing straw into boards without adhesives was developed in the 1930s. These panels, typically 2 to 4 inches thick, feature heavyweight kraft paper on each side. They also function as effective sound-absorbing panels for interior partitions. Some manufacturers have created structural insulated panels from compressed-straw panels.

Hemp:

- Hemp insulation, although less commonly used in the United States, offers a sustainable option. Its R-value is comparable to other fibrous insulation types.

These natural fiber insulation materials contribute to environmentally conscious construction practices. They often undergo treatments, such as borate application, to enhance resistance to pests, fire, and mold. As sustainability gains prominence in the construction industry, the use of these natural fibers is likely to see continued interest and adoption.

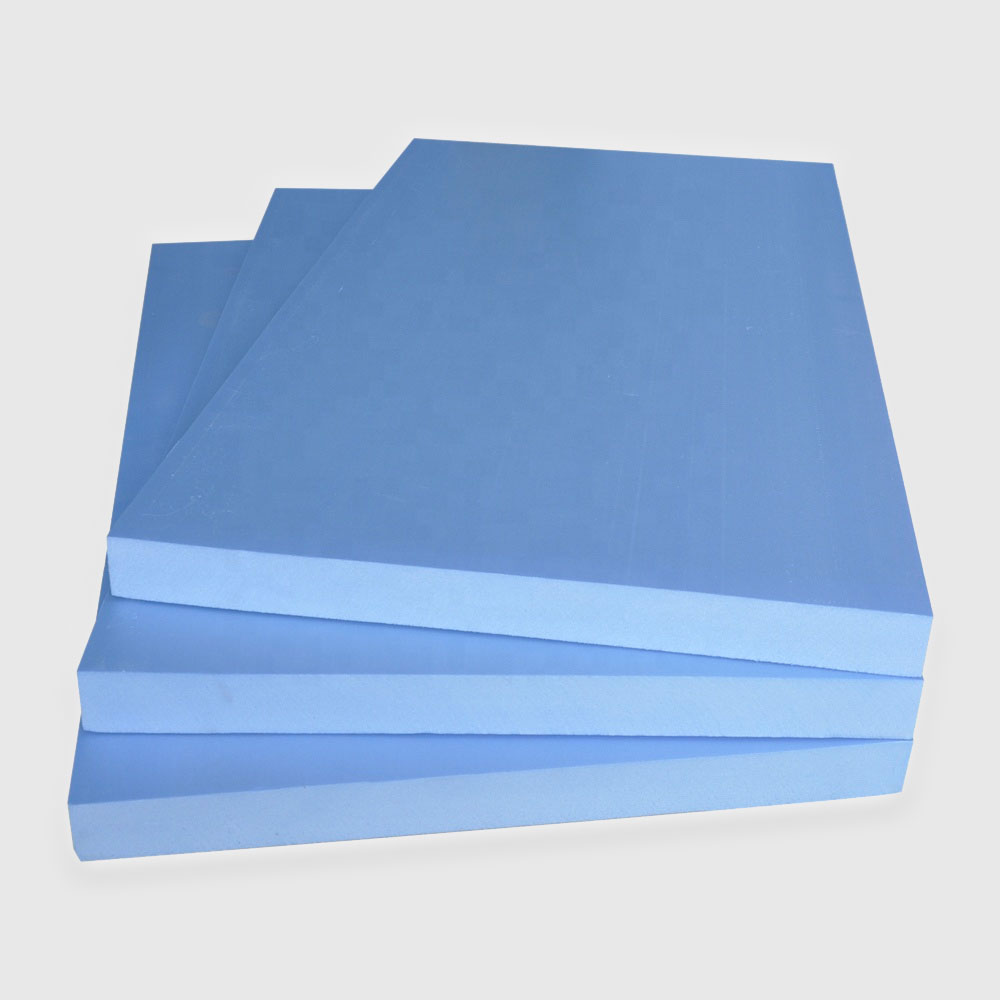

Polystyrene Insulation Materials